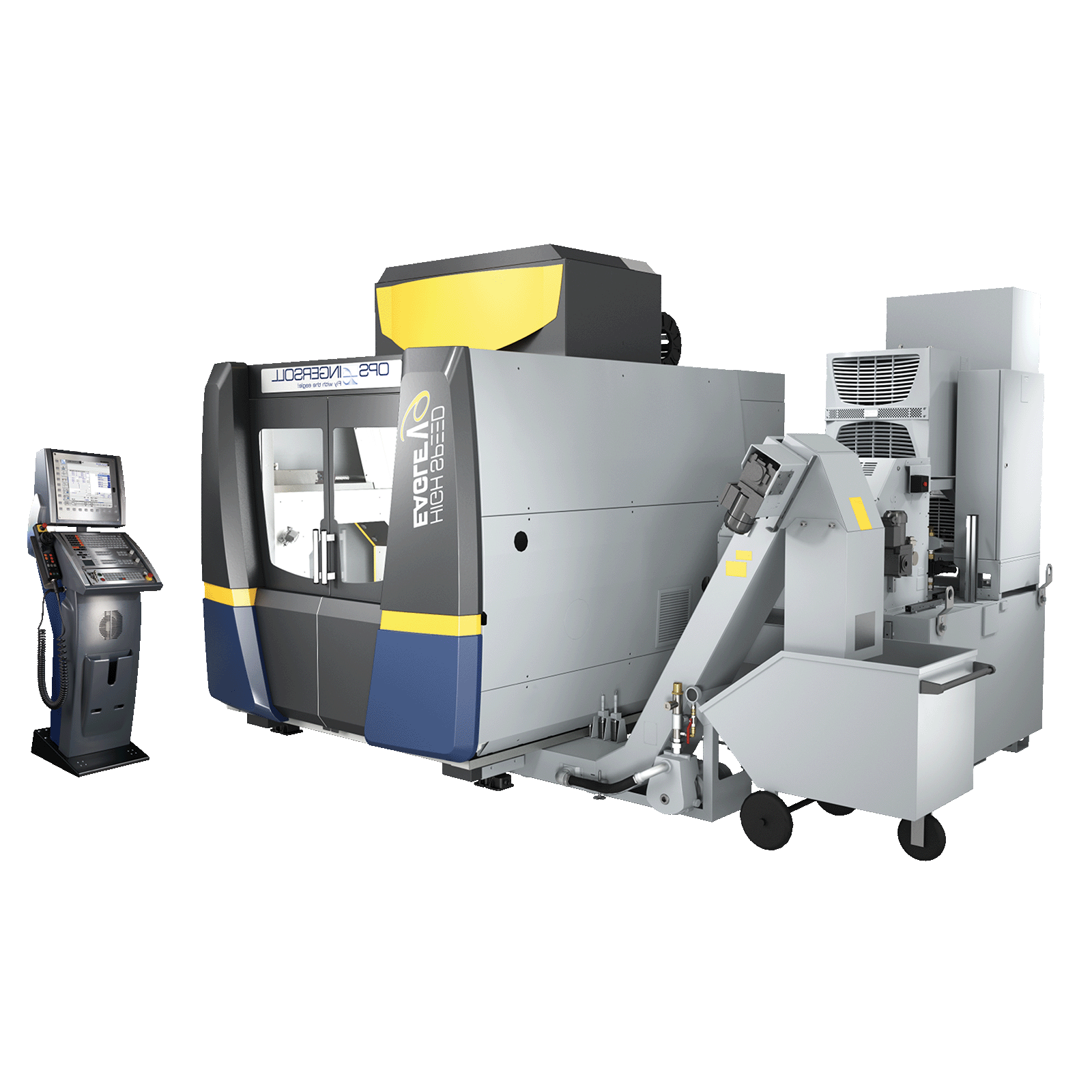

Mega sss-400/600 5axp(5轴)

的高精度, high-precision fusion of 5 axis technology for your micro-fine milling and small-hole drilling needs.

When the job calls for high-precision cutting, you use a 5-axis milling machine. 但有时还有其他因素需要考虑, and not all 5-axis milling machines are created equal. For some projects—the kind that require fast, 准确的 results down to the 1,000th of a millimeter—you need a machine that’s up to the task.

The MEGA SSS family of 5-axis machining centers combine high-speed machining (40,000和60,000 RPM通过400和600版本, (分别)具有微精细的细节处理能力, allowing 你的商店 to reliably tackle small-hole drilling, micro-accuracy加工, 和更多的.

Come see what a difference a true hybrid milling machine can make—for your customers, 你的商店, 和你.

微细加工,效率最大化

- 通过快速提供高精度切割, MEGA SSS-400/600 5AXP使您更有效率, 让你更好地掌控自己的业务.

跑得快,经久耐用

- The MEGA SSS-400/600 5AXP combines rugged construction materials and dynamic internal components to enable continuous operation at max speed—without compromising quality.

为你的车间带来平衡

- By offering multiple milling capabilities all in one single machine, the MEGA SSS-400/600 5AXP lets you handle more than ever before—backed up by best-in-class support from our responsive service teams.

功能:

- Ideal for both small-hole drilling and micro-fine 5-axis milling through its unique “super hybrid” design

- Allows simultaneous 5-axis control with a special design for optical encoder feedback on the rotary unit

- 宽速度范围(3),000到40,000 RPM (400), (3,000至60,000 RPM for the 600) via an oil-mist lubricated spindle and a long-life AC motor

- Capable of 5-second tool changes, thanks to 20-position twin arm-style tool changer

- Provides both high-precision 3-axis positioning and additional 2-axis indexing accuracy

- Operates across a wide speed range via an oil-mist lubricated spindle and a long-life AC motor

- Provides excellent shock and vibration dampening for high-speed, high-precision machining and greater stability via high-rigidity structure and Meehanite GC castings for both the base and bridge

- Built to jig-grinder standards of quality and accuracy with bridge construction that eliminates the X axis table overhang commonly associated with C-frame construction designs

- New tool measurement device location “Blum 激光” is relocated to an out-of-stroke position

- A pneumatic counterbalance is located on the spindle headstock providing smooth, 准确的 movement of the Z axis during high-velocity contouring and drilling

- 具有增加的传送门高度(7.9“/200mm)用于添加A/C轴单元

组件:

- 高刚性Meehanite结构

- 高刚性HSK-E40刀架, allowing 6x higher clamping force than a regular BT shank for highly reliable work

- 滚柱式直线运动方式

- Z轴热生长补偿

- Non-contact tool measurement (Blum 激光) with air-blow cleaning

- 双Z轴平衡气缸

- X, Y, Z轴线性尺度

- 7加仑油箱的主轴冷水机

- 80加仑冷却液罐标准

用户界面:

- Fanuc 31i-B5超高速加工, 纳米平滑, AI等高线控制II, 和NANO插值

- 1000块前视块扩展

- Super PC III function with 3-mode operation to balance speed and accuracy

| 机器行程:X X Y X Z in (mm) | 16.0 x 13.0 x 7.9 (400 x 330 x 200) |

|---|---|

| 主轴转速(600) | 3000 ~ 40000 RPM (60000 RPM) |

| 主轴惠普 | 4.7 |

| 主轴润滑 | 油雾 |

| 换刀器尺寸 | 20位标准(40或60可选) |

| 定位精度/重复性:in (μm) | ±0.000040/±0.000012 (±1.0/±0.3) |

| 转盘面板:in (mm) | Ø 3.94 (Ø100) |

| 马克斯. 倾斜a轴角度:度. | -120 ~ +10 |

| 回转c轴指标精度 | ±1.5弧秒. |

| 倾斜a轴指标精度 | ± 3.5弧秒. |

| 面板到主轴机头距离:in (mm) | 1.07 ~ 8.94 (27 ~ 227) |

| 马克斯. 工件重量:lb (kg) | 20 (44) |

| 冷却液罐容量:加仑(L) | 37 (140) |

| 面板距地面高度:in (mm) | 38.3 (973) |

| 实际测量圆度(2.0”迪亚. @8 IPM): in (μm) | 0.000039 (1.0) |

| 主轴锥度 | HSK-E25 |

| 主轴空气吹扫 | 标准 |

| 经主轴吹风 | NA |

| 带收集器的油雾 | 可选 |

| 线性尺度X, Y, Z轴 | Heidenhain 0.000002毫米标准 |

| 快速遍历速度:in/min. (米/分钟.) | 590 (15.0) |

| 切割速度(普通模式):in/min. (毫米/分钟.) | 0.04 – 394 (1 ~ 10,000) |

| 切割速度(GR Super PC模式):in/min. (米/分钟.) | 590 (1.5) |

| 集尘系统 | NA |

| 机器重量:lb (kg) | 6173 (2800) |

| 机器高度:in (mm) | 90.1 (2290) |

| 所需占地面积:单位:mm | 79.1 x 106.0 (2010 x 2690) w冷却剂冷水机选项 |

| 控制单元 | Fanuc 31i-B5 Super High-Speed Processor, Al Contour Control II and 5-Axis machining package |

| 功率要求KVA | 200 ~ 220vac: 14.0 kva (16.5kVA(可选) |

| 空气供给 | 9 cu.ft./min≤72 psi |

相关解决方案

-

五轴加工技术

高速, high-precision machines with the power and flexibility to meet any challenge.

了解更多 -

直线驱动技术

Hyper-准确的 machinability for tight tolerances and micro-fine work where the details really matter.

了解更多 -

高速加工

Top-of-the-line machinery with added cooling power for consistent performance on mission-critical tasks.

了解更多 -

石墨制造

Multiple solutions and expertise in making graphite electrodes.

了解更多 -

铣削自动化

Multiple solutions and expertise in making graphite electrodes.

了解更多

-

"Not only does the 5-axis capability of the OPS Ingersoll Eagle V5 milling machine enable us to burn parts with less physical electrodes, it also has a robotic tool changer so we can focus more during the day on things that need constant attention."

布拉德·麦克道尔, 质量工具 & 死的总统 阅读案例分析 -

-

"The Eagle 800 has burn technology that gives us a competitive advantage because it takes about half the time to burn and uses fewer electrodes, 这样既节省时间又节省金钱. bt365体育娱乐的目标是整天和整个周末都跑. I like that we also are cutting down on our carbon footprint by using fewer graphite electrodes and less copper wire than before."

史蒂夫(, 零容忍总统 查看案例研究 -

-

-

"The kinematics of the Roku-Roku VMCs allow us to run faster feed rates and not sacrifice surface finish or accuracy. The machines are efficient in terms of increased cutter life, 可靠的发那科控制和整机稳定性. We can run longer intervals on downstream inspection on parts that the Roku-Rokus machined."

约翰TerBeek, 特贝克模塑公司的合伙人 & 工具 查看案例研究